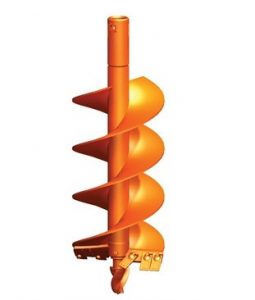

Tips to Select Best Auger Teeth for Your Drilling Equipment

When it comes to drilling works, having the right tools is the most important thing. You need to consider the kind of wear tools that you are working. Among the key parts, you need to consider are auger teeth. That is why selecting auger teeth for your drilling machine crucial.

The most important thing that you need to consider while selecting auger teeth are features that make good cutter tools. But what are the key things that you need to look for? Well, there are a number of things that make good auger teeth. Here are key things that you need to take into account:

Quality of Material

The first thing that you need to consider is the material used for auger teeth(click here to know more about it) construction. In drilling, it is essential to check the quality of the grade of material used for the construction of teeth, especially if you are buying aftermarket auger teeth. It is important to note that the quality of tooth is not determined by looks or brand but the material used for its construction. The highest grade of tungsten carbide for the teeth tip. Forged steel or carbon alloy is recommended for the teeth body. But if you are shopping from the original manufacturer, quality is guaranteed.

Size of Teeth

You need to check the size of the teeth while buying. That is important if you are buying for the first time. Get the size of the teeth including the actual length of the teeth depending on the machine and the conditions you are drilling. That will ensure you are getting the right teeth for the teeth. The second thing to check is the diameter of the teeth shank. The diameter of the teeth should be large enough to withstand the pressure produced by the drive without breaking. If you are making a replacement, get the same size exact teeth.

Nature of Tip

There are various models of teeth tips in the market. However, the most important thing that you need to consider is what works for you. Depending on the kind of drilling you will be doing, it is important to select the right tip. There are three types of tips to pick from including plug, cap and narrow bottom tips. Plug tip has a physical lock between while cap joint relies on brazing technology. The narrow bottom is a combination of the two tips and most powerful. Therefore, pick what works for you.