Deep drawing press machines are a crucial component in the manufacturing industry. They play a vital role in forming sheets of metal into desired shapes without tearing or wrinkling. However, over time, the performance of these machines can decline. If you’ve noticed a drop in your deep drawing press machine’s efficiency, it’s crucial to understand the potential reasons behind it. Here are five common factors that could be affecting its performance:

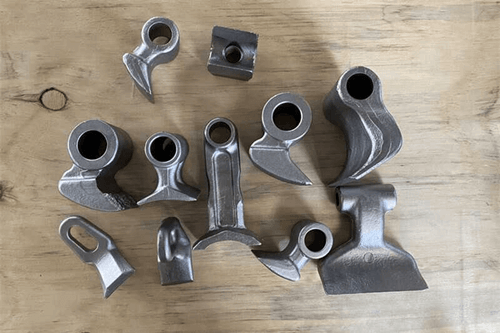

Wear and Tear of the Dies

The die used in a deep drawing press machine undergoes significant stress during the operation. Regular use can result in wear and tear, which can affect the quality and precision of the formed parts. A worn-out die can cause uneven pressure distribution, leading to defective parts.

Solution: Regularly inspect and maintain the dies.

Inadequate Lubrication

Lubrication is essential to ensure smooth operation and reduce friction between the die and the metal sheet. Inadequate or irregular lubrication can result in increased resistance, causing the machine to work harder and reducing its lifespan.

Solution: Develop and stick to a regular lubrication schedule.

Malfunctioning Hydraulic System

Deep drawing press machines rely heavily on their hydraulic systems to produce the necessary force. A malfunctioning hydraulic system can reduce the machine’s effectiveness and increase the cycle time.

Solution: Regularly inspect the hydraulic system for any leaks, air bubbles, or other issues. Ensure that the hydraulic fluid is at the recommended level and is of good quality.

Misalignment of Components:

Over time, the repeated stress on the machine can cause components to become misaligned. Misalignment can lead to uneven force distribution, resulting in inferior quality products and even machine damage.

Solution: Regularly inspect the machine for any signs of misalignment.

Inaccurate or Old Control Systems

Modern deep drawing press machines come equipped with control systems that regulate various parameters during operation. An outdated or malfunctioning control system can reduce the efficiency and precision of the machine. Update or replace outdated control systems.

For more about the deep drawing press machines and more so their prices and quality, read more.